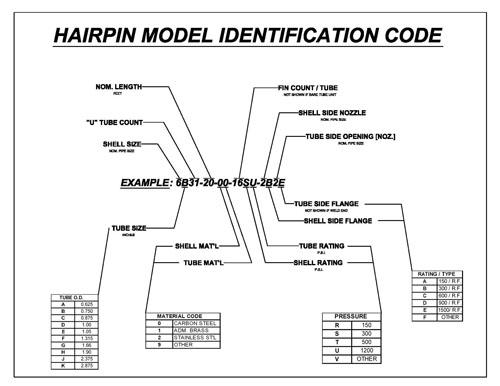

Hairpin Heat Exchanger

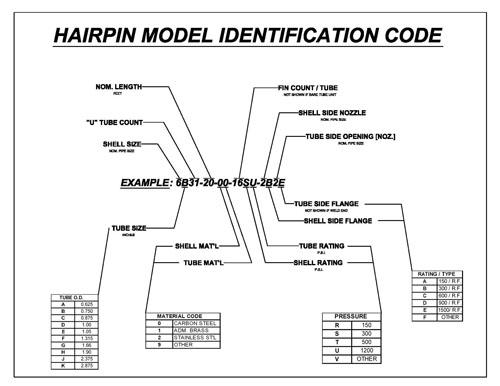

HEAT EXCHANGER DESIGN,INC. offers a complete line of Hairpin Exchangers. These exchangers provide true counter-current flow and are especially suitable for extreme temperature crossing, high pressure, high temperature, and low to moderate surface area requirements.

Our Hairpin Exchangers are available in single tube (Double Pipe) or multiple tubes within a hairpin shell (Multitube), bare tubes, finned tubes, U-tubes, straight tubes (with rod-thru capability), fixed tube sheets and removable bundle. The surface area ranges from (1) square foot to 6,000 square feet (Finned tubes).

Pressure capabilities are full vacuum to over 14,000 PSI (limited by size, material, and design condition). Hairpin Exchangers are designed and fabricated per ASME code, and TEMA standards.

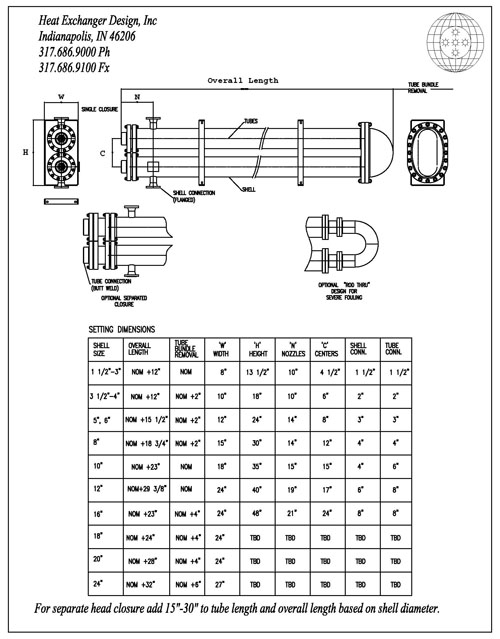

Click on this image for a PDF Printable Brochure

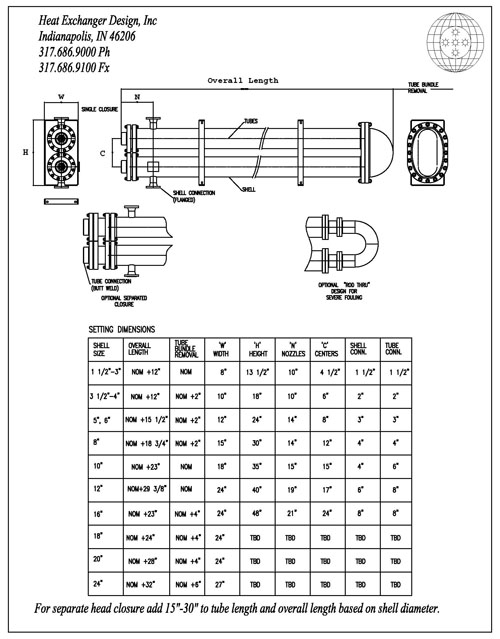

1. Double-pipe Hairpin Bare and Multi-tube (Table 1 & 2): These units are constructed using U shape tubes or pipe that are attached to two tubesheets and are loaded inside a hairpin shape shell. |

Advantages:

- Tube bundle is removable; therefore mechanical cleaning is possible on the shell side.

- The U shape bundle is free for expansion and contraction inside the Hairpin shell eliminating the need for expansion joint.

- Are capable of carrying the maximum pressure allowable by ASME Code per given wall thickness. (Up to 14600 psi with no corrosion allowance). Higher pressure ratings are possible using materials with higher stress values

- For processes that require frequent mechanical cleaning, bare tube offers ease of cleaning and accessibility.

- Bare Multi-Tube and Double-Pipe Exchangers offer the least pressure drop among most exchangers.

- Very often a process might be modified or completely changed. The streams flow rate or other conditions might also change. A Double Pipe Hairpin is designed so as to accommodate these changes, simply by rearranging the sections. Unlimited numbers of sections could be arranged in parallel and series to fit new requirements of the process conditions.

|

Limitations:

- Only chemical tube side cleaning is possible.

|

Click here to view Table 1

Click here to view Table 2

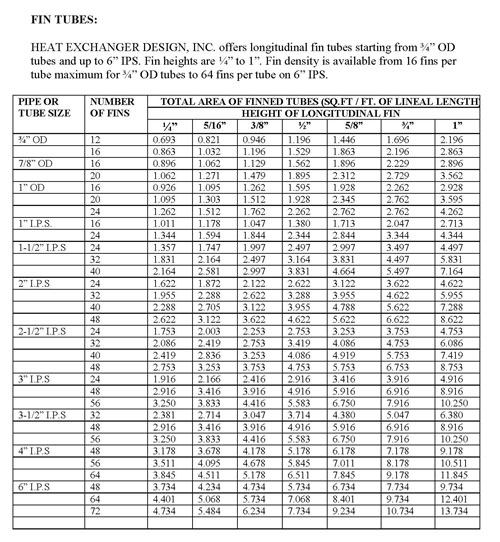

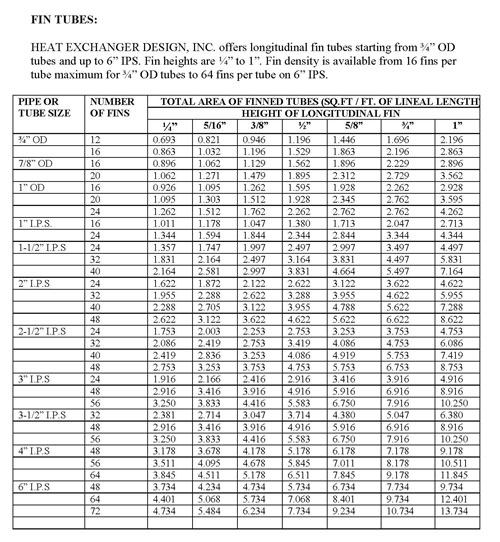

2. Finned Double Pipe & Multi-tube (Table 3 & 4): |

Advantages:

- The same advantages as the bare tubes above (A, B, C, E, and F)

- The finned hairpin usually has up to four times more heat transfer surface than bare tube hairpin. This would especially be more advantageous when the shell side heat transfer coefficient is low, therefore requires more surface

- Good application for high shell side viscosity with low heat transfer coefficient. Finned hairpins are particularly good application for cooling viscous fluids. The viscosity on the fin wall is higher than the average bulk viscosity which produces a lower film coefficient on the fin, and reduces heat transfer and causes excessive fouling.

|

Limitations:

- Only chemical cleaning of the tubes finned surface is possible.

|

Click here to view Table 3

Click here to view Table 4

Click on this image for a PDF Printable Document

Click on this image for a PDF Printable Document

12 high pressure Hairpin Exchangers for offshore applications.

|

26 in Hairpin 3500 psi pressure for offshore installation

|

A bank of Hairpin Exchangers

|

Assortment of Hairpin Exchangers

|

CO2 Cross Exchanger all stainless 1050 design temp

|

Fixed Tube Sheet Hairpin Exchanger for high pressure high temp gas application

|

HED Separated Head Closure using separate bolting shell and tube side

|

HED Standard Separated Seal Closure using common bolting

|

Multi Tube Bundle with turbulators for glycol application

|

|

|

|

|